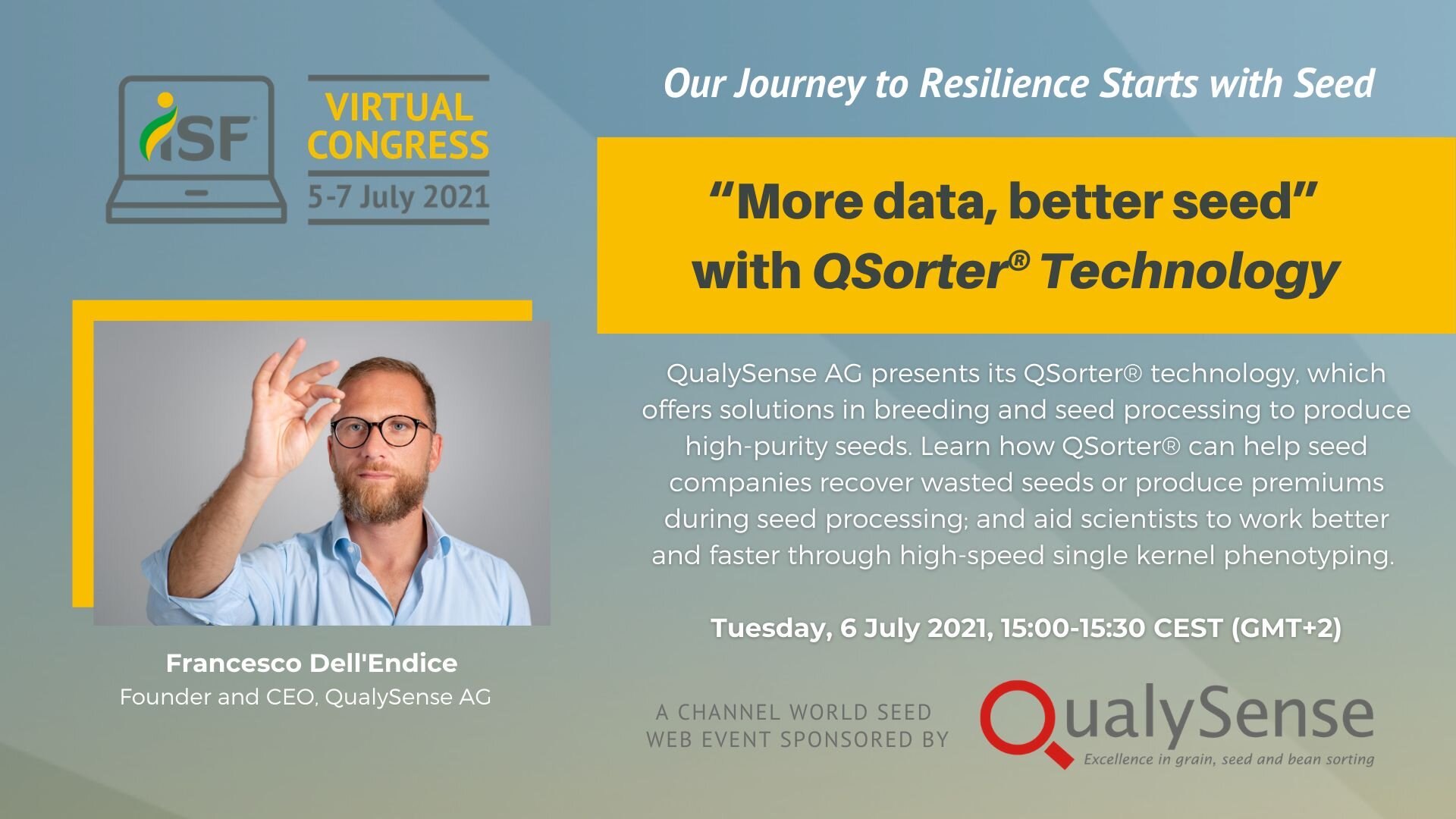

More Data, Better Seeds. Francesco live at ISF webinar

Join a live discussion with Francesco, founder and CEO of QualySense, about how to use the QSorter® technology to collect quality insights and produce seeds with higher purity.

Virtual Congress organized by International Seed Federation on July 5-7, 2021.

Register here: http://congress.worldseed.org/

Producing High-Purity Seeds

Seed companies aim at producing seeds lot with high purity and various technologies are used to either assess purity levels, i.e., testing methods, or to increase purity during processing by discarding low performing seeds, i.e., sorting technologies.

Purity could be of 3 types:

Genetic purity

Germination purity

Physical purity

The purity of a seed lot could be assessed by (1) measuring phenotyping parameters, either compositional (e.g. oil, sucrose) or physical (e.g. size, color), or (2) indirect measurements.

Reasons for using QSorter® in breeding

During the breeding process, scientists select which seeds to bring into the next generation by means of phenotyping tests, genetical tests and field trials. The phenotyping tests are generally slow, expensive, and destructive and, therefore, only a few seeds are analyzed, which does not allow to produce results with a strong statistical confidence. In addition, different types of equipment need to be used to measure all the desired parameters.

· The QSorter® Explorer is a high-speed single kernel phenotyping that helps scientists breeding better and faster.

· Some of its key features are:

· Measurement of several phenotyping parameters in one pass

· Automatic selection of the desired seeds

· Quality distribution for each measured parameter

· Single seed speed up to 30 per second to create large sets

· Non-destructive and non-invasive analyses

Reasons for using QSorter® in processing

During multiplication or production, several good seeds may be lost because of purity problems, low machinery efficiency or because their quality changes with time. Purity is measured on an average basis and a low purity batch still contains several good seeds (at least 50%). As of today, seeds with a physical purity below the market threshold could be partly recovered with mechanical or color sorters but, good seeds belonging to lots with an average low genetic or germination purity must be wasted.

The QSorter® technology is now changing this and can help seed companies recovering wasted seeds or producing premiums.

Some of its key features are:

· Measurement of several purity parameters in one pass

· Automatic selection of the desired seeds

· Single seed speeds up to 3’0000 per second

· Non-destructive and non-invasive analyses