QSorter® Technology

The state-of-the-art tech for grading and sorting grains, seeds, and beans

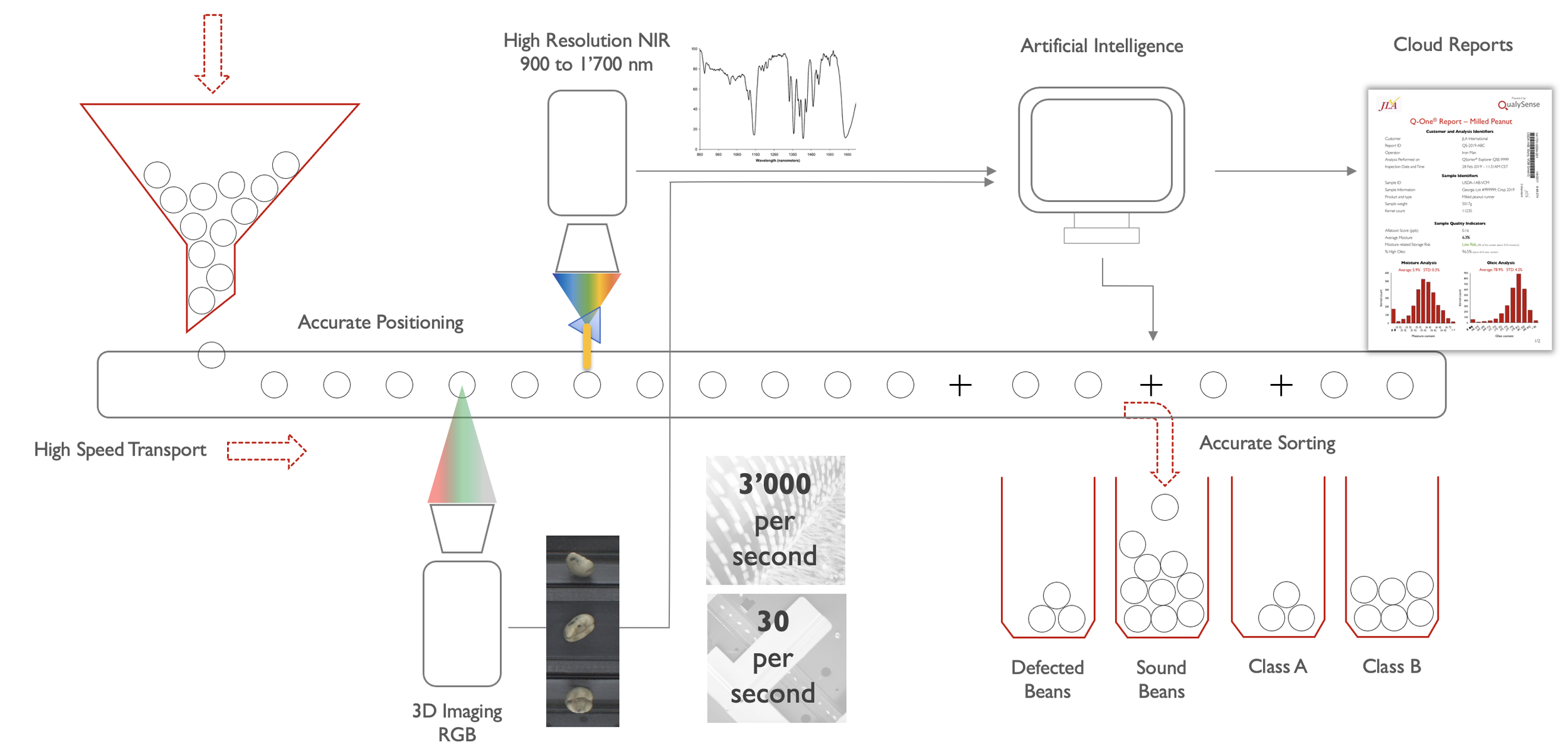

From 30 to 3’000 kernels per second: discover our platforms

QSorter® Explorer

QSorter® Explorer

The ideal data and sorting solution for:

Ultrafast Breeding

Automatic Quality Inspection

Research & Development

QSorter® Horizon

QSorter® Horizon

The ideal data and sorting solution for:

Waste recovery

Creation of premium seeds, foods, and drinks

Continuous processing quality control

The QSorter® technology is at the heart of a cutting-edge series of inspection and fine-sorting devices for grains, seeds, and beans. Since 2010, QualySense has pioneered this technology, supported by top research institutes in Switzerland and in the USA, to enable seed, food, drink, and agri companies to extract an unprecedented amount of quality data from grains, seeds, and beans so that users can sort with respect to new quality parameters, therefore increasing productivity and reducing waste.

3D Imaging

The 3D imaging sensor allows the QSorter® to inspect a great portion of the surface of the kernel and detect several properties and defects. The wide-angle optics are designed to cover almost 100% of the seed’s surface for a more accurate inspection of physical characteristics and defects. The CCD high-speed color camera can process up to 120 frames per second, with flexible illumination setups that help see the previously unseen. The fixed position of the grain allows the camera to record physical attributes such as shape, length, width, height, volume, color, and defects with great precision. Further analysis is applied to retrieve even more complex parameters such as the level of chalkiness and small defects.

High-Res NIR Spectroscopy

The QSorter® is the only tech using a High-Resolution Near-Infrared (NIR) Spectrometer in the spectral range 900 nm - 1’700 nm. A light source illuminates the kernel; the light rays are either transmitted through the kernel, absorbed by the kernel or diffusively reflected. The difference between the injected amount of light and the one that is reflected is proportional to the chemical structure of the seed, which allows the precise measurement of compositional quality properties such as protein, moisture, oil, sucrose, and many more, which are key to understand the value of the raw material and to optimize production for better consistency.

99% Accurate Sorting

The QSorter® sorts with a very high efficiency, close to 100%. This is the result of long research on our proprietary single kernel transport system and on a high-precision sorting mechanism, which are based on cutting-edge mechatronics and pneumatics systems. This high accuracy is key in ensuring a highly precise quality inspection or a very efficient high-capacity selection process. The QSorter® can sort seeds into up to 5 classes; this very innovative feature enables users to sort the beans with respect to multiple parameters in just one pass. The sorted fractions can be easily collected either into baskets or directed to silos.

The Qsorter® Explorer installation and performance went all fine. In addition, the tests that we have been performing are running out normally. The operating detailed instructions were carried out accordingly without any setback. We have noticed that as more tests were carried out, the evaluation of the results gave us a better definition of what is a good and healthy sample from what is a bad and damaged cup. We needed to stop and were on hold for a while due to the current circumstances, but we have resumed the tests and the whole process was carried out again without any problem.

William Diaz – Becamo, Neumann Kaffee Gruppe

High Mechatronics Precision and AI Algorithms

QSorter® technology scheme

The signals of the High-Resolution Near Infrared Spectrometer and of the 3D Imaging Sensor are correlated to Wet Chemistry measurements or Visual Standard Inspection Practices, which define the "true" measurements. Such correlations are designed by a team of algorithm experts by means of various technologies such as Artificial Intelligence, Machine Learning, Regressions, and many others. Furthermore, the algorithms learn over the seasons to produce robust and repeatable performance.

Artificial intelligence algorithms

Q-One® Digital Report

The QSorter® results are visualized on a friend Graphical User Interface. Several statistical metrics such as mean value, count, and standard deviation are reported for each measured parameter at batch/lot level as well as at single kernel level. Furthermore, data are stored in the Q-One® Digital Report, which can be easily shared with colleagues and used to analyze the performance of the laboratory or of the plant over one or multiple seasons. The report can be customized to our organizational needs to include also other key data. Printing in the most common formats is, of course, enabled.